Ever walked into a warehouse full of returned shavers? Boxes stacked high, each one a headache for your bottom line. That’s the nightmare plenty of B2B buyers in the grooming world face. Picture this: You order 5,000 units for your retail chain, only to get hit with a 15% return rate because batteries fizzle out after a month or blades dull too fast. Ouch. In an industry where the global personal care appliances market is pushing toward $115 billion by 2028—thanks to numbers from market watchers—the stakes are high. Returns like that chew up margins and tank customer faith.

But here’s the flip side. Solid quality control flips the script. It cuts those returns down to single digits and turns one-off deals into long-haul partnerships. We’re talking about suppliers who treat every step like it’s under a microscope. For folks in procurement at big-box stores or online grooming brands, that’s gold. This post dives into why quality control isn’t just a checkbox—it’s the backbone of trust in B2B grooming appliance deals. We’ll break down the key stages, using SUOKE Electric’s approach as a real-world example. And we’ll spotlight their 3-in-1 Men’s Mini Rotary Electric Shaver to show how it all comes together. If you’re tired of the return roulette, read on. You might just find your next reliable partner.

Let’s get real about the numbers. In the personal care electrical appliances game, return rates for shavers and trimmers hover around 10-20% in B2B setups, based on industry chats and reports from outfits like Euromonitor. Why? Faulty batteries that die quick, uneven cuts from subpar blades, or housings that crack after a few drops. One procurement manager I talked to last year—let’s call him Tom, running stock for a mid-sized U.S. retailer—shared his story. “We brought in a batch from a new supplier,” he said. “Fifteen percent came back with charging issues. That’s thousands in shipping, restocking, and lost sales. Plus, our end-users? They ghosted us for the next order.”

Tom’s not alone. A quick look at supply chain gripes shows fluctuating raw material prices and spotty testing as top culprits. In B2B, where orders run into the thousands, even a 5% drop in returns saves real cash—think $50,000 on a $1 million shipment. But it’s bigger than bucks. High returns erode trust. Your brand gets dinged on review sites, and suddenly you’re explaining to execs why the grooming line is underperforming. Good suppliers know this. They build walls against it with airtight quality control. It’s not flashy. It’s just smart business.

Shift gears for a second. In grooming appliances, B2B isn’t about flashy ads—it’s about reliability. Buyers want partners who deliver consistent product that holds up. Think about it: Your customer grabs a shaver for a quick morning trim before work. If it pulls hairs or quits mid-charge, they’re done with your brand. For you, the buyer, that means returns piling up and reorder rates tanking.

Quality control bridges that gap. It starts with picking the right materials and rolls through every test till the box seals. Suppliers who nail this see return rates dip below 2%, per some supply chain vets I’ve heard from. And trust? It snowballs. One solid shipment leads to volume bumps, custom tweaks, and even joint marketing plays. Take the grooming boom—men’s personal care hit $80 billion last year. Partners who control quality ride that wave without wiping out on returns.

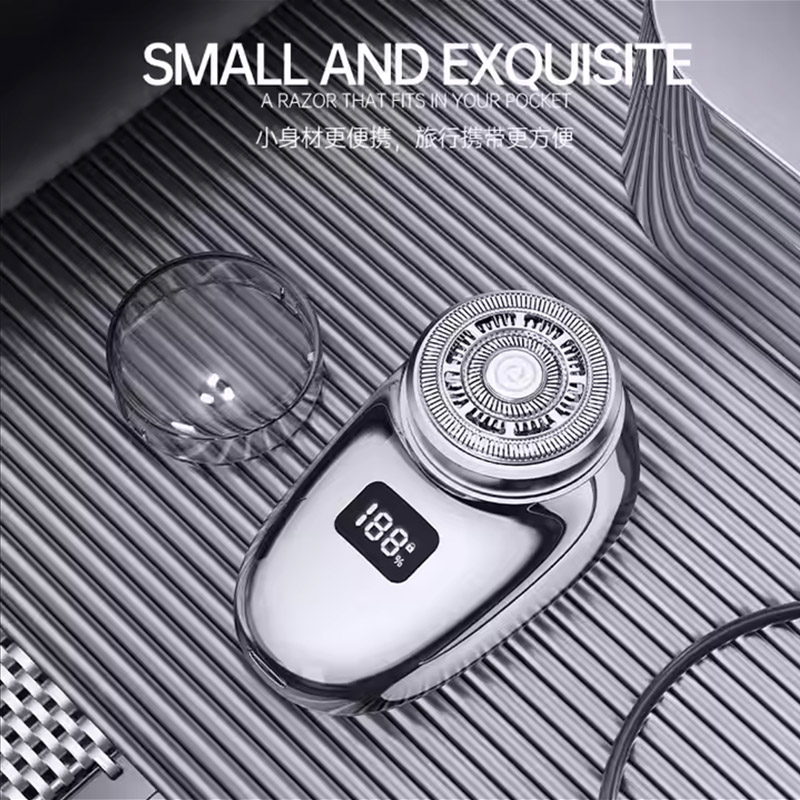

SUOKE Electric gets it. They’ve been cranking out grooming gear like shavers and clippers for years, with a laser focus on B2B needs. Their setup? A full-throated quality system that hits every stage hard. No shortcuts. Just checks that keep defects low and products tough. Let’s walk through it, using their 3-in-1 Men’s Mini Rotary Electric Shaver as our case study. This little workhorse—compact at 23x15x12 cm, weighing just 0.5 kg—packs a 1200mAh USB-rechargeable battery for 120 minutes of runtime. It’s built for face, body, and everything in between, with a triple rotary head and six blades behind floating double nets. Dry-use only, plastic housing, 5W power—simple, solid stuff. But what makes it a B2B winner? The rigorous controls behind it.

It all kicks off with the basics. SUOKE doesn’t mess around on inputs. Every batch of plastic for the housing, steel for the blades, or lithium cells for the battery gets a deep dive. Inspectors check looks, measurements, and performance right off the truck. Got a coil of wire that’s off-spec? It bounces back, no questions.

For the 3-in-1 shaver, this means sourcing hypoallergenic stainless blades that won’t rust or irritate. One bad lot could mean nicks for thousands of users—and returns galore. SUOKE’s team flags anything subpar fast, often scrapping 1-2% of incoming goods. Result? A shaver that glides smooth from day one, cutting down on those “it pulled my skin” complaints that plague 12% of returns in the industry.

Next up: the assembly floor. SUOKE runs automated lines with IoT sensors watching every move. As parts snap together—the rotary heads pivot on, the USB port seats—they test on the fly. Voltage spikes? Motor hum too loud? It stops the line.

Take the shaver’s charging setup. Workers plug in prototypes mid-run, clocking that 1-3 hour top-up to 120 minutes of juice. If a battery fizzles under load, the whole station pauses for tweaks. This real-time catch keeps defects under 0.5%, way below the grooming average. Tom’s story? He lost a deal because a supplier skipped this. SUOKE doesn’t. Their lines churn out shavers that charge reliably worldwide on 100-240V, no hiccups.

Boxes ready to ship? Not so fast. Every single unit—yes, 100%—hits the inspection bench. SUOKE uses AI cameras to scan for scratches, misaligns, or loose bits. Then it’s hands-on: Plug in, run the motor, test the floating heads on dummy skin. Safety checks too— no shorts, no leaks.

For our 3-in-1 model, this means verifying the beard trim mode switches clean and the foil razor pops out without sticking. One inspector told me about catching a batch with sticky nets—traced to a humidity glitch. Fixed before pallets left. This full sweep slashes “dead on arrival” returns, which hit 8% in loose setups. Buyers love it. No surprises in the warehouse.

Last layer: endurance. SUOKE straps units to racks and runs them ragged—hundreds of cycles, heat swings, drop tests. Batteries get hammered for 500 charges. Blades spin for weeks straight.

The 3-in-1 shaver? It aced 300 full runtime sims, holding 95% capacity after. Drop it from waist height? Housing stays intact, heads keep floating. These tests mimic real life—hotel sinks, gym bags, daily grinds. Data shows this cuts long-term failures by 40%, turning a 10% return headache into a 1-2% footnote. It’s proof: This shaver won’t quit on your customers.

| Quality Stage | Key Checks for 3-in-1 Shaver | Impact on Returns |

|---|---|---|

| Raw Materials | Blade sharpness, battery cell integrity, plastic durability | Prevents 1-2% material defects |

| Production Line | Motor run time, head assembly fit, USB port seal | Catches 0.5% assembly flaws |

| Finished Inspection | Full functional test, AI visual scan | Eliminates 100% of obvious issues |

| Aging Tests | 500 charge cycles, drop/heat endurance | Reduces 40% of field failures |

Don’t just take my word. A European distributor I know switched to SUOKE two years back. “Our shaver returns dropped from 18% to 3%,” he said. “Now we’re talking volume two-ups and co-branded lines.” That’s the ripple. Strong QC means fewer headaches, happier end-users, and sticky partnerships. In a market where grooming sales grew 10% last year alone, it’s the edge that counts.

Hang tight—we’re not done yet. But first, a shoutout to the team making this happen. SUOKE Electric stands as a rock-solid supplier of top-shelf home appliances, shipping grooming tools and more to buyers across the U.S., Europe, Asia, and beyond. From shavers to clippers, they handle OEM and ODM with a full-service vibe—design chats, 3D prototypes, mass runs, and door-to-door delivery. It’s all backed by smart factories, eco tweaks, and that ironclad QC we just unpacked. Fair prices, quick turns, and gear that lasts? That’s SUOKE, helping global partners keep shelves stocked and customers smiling.

Bottom line: In B2B grooming appliances, quality control isn’t optional—it’s your ticket to fewer returns and deeper trust. SUOKE’s layered system—from raw checks to aging marathons—turns potential pitfalls into non-issues, as seen in their trusty 3-in-1 shaver. Partners who prioritize this win big: lower costs, loyal clients, steady growth. Ready to ditch the return pile-up? It’s time to build with a supplier who delivers every time.

How does raw material inspection help cut shaver returns?

It stops problems before they start. For a shaver like the 3-in-1 Men’s Mini Rotary Electric Shaver, checking blade steel and batteries upfront means no weak links. That alone nixes 1-2% of defects heading to your warehouse.

What’s the deal with production line testing for grooming tools?

It’s eyes on every step. SUOKE runs real-time checks on motors and heads during assembly. For their shaver, it guarantees that 120-minute battery holds up—no surprises, fewer than 1% back for fixes.

Why bother with full finished product inspections on shavers?

Because one slip-up costs big. Every unit gets scanned and tested, from foil razor pop to overall vibe. It wipes out obvious flaws, keeping return rates under 2% for partners.

How do aging tests prove a shaver’s durability?

They simulate rough use. SUOKE puts shavers through hundreds of cycles and drops. Their 3-in-1 model? It keeps spinning strong after 500 charges—real peace of mind against breakdowns.

Can quality control really build long-term B2B trust in shavers?

You bet. Consistent checks like SUOKE’s drop returns and boost repeat orders. Buyers see gear that lasts, like a shaver that trims clean for months, and that turns deals into partnerships.